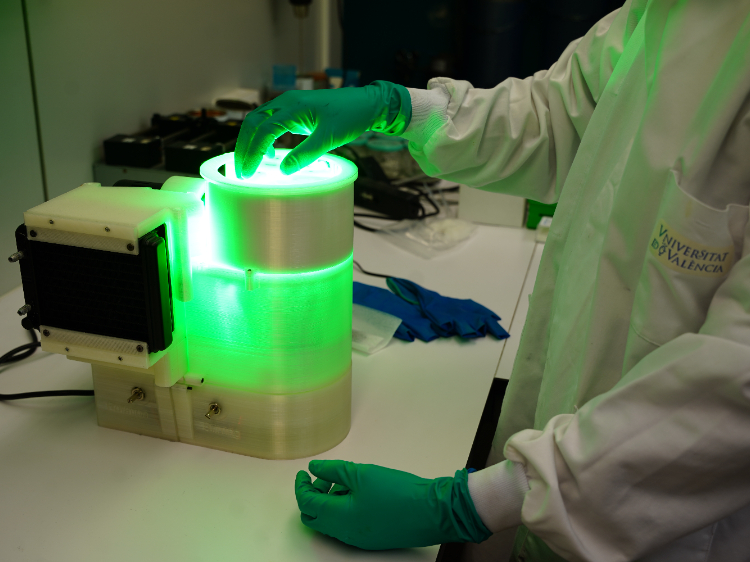

The research group on Functional Inorganic Materials (Funimat) at the Institute of Molecular Science (ICMol) of the University of Valencia has designed and patented a high-performance photoreactor for chemical reactions that, in addition to being small, simple and compact, is manufactured in a 3D printer with light and cheap materials. The prototype has obtained funding from the Valencian Innovation Agency (AVI) of the regional Government of Valencia for its improvement, commercialisation and use in the rapid and reproducible valorisation of CO2.

The prototype allows the development of standardised and highly efficient reaction protocols. It integrates the light source responsible for the "excitation" that causes the chemical reaction. The lamp is associated with a rotating carousel on which, like a magnetic stirring plate, up to 10 vial holders with analysable material can be placed. The reactor, named PhotoSpinner, is safe and practical because it can be used with commercial stir plates.

The photoreactor incorporates an internal cooling fan that keeps the reactions close to room temperature. This avoids overheating of the mixtures, which is common in current systems that do not have much control over the distance to the lamp, the ambient temperature or the local airflow.

The conversion of CO2 using solar energy (artificial photosynthesis) has great potential to provide clean alternative fuels and solve the problems related to global warming. In fact, photochemistry is an area that scientists have turned to in recent years because many of the transformations brought about by a light source (usually LED lamps) open the way to products that were previously difficult to synthesise.

However, these technologies present problems such as the low conversion efficiency shown by the available photocatalysts. It is therefore essential to develop new photocatalysts adapted to guide the conversion of CO2 into value-added products (methane, for example) under conditions of varying humidity, temperature or CO2 concentration. This requires accelerated, rapid and reproducible testing of several compounds at the same time. This is the so-called HTS (High Throughput Screening), which the Photospinner project intends to perfect by adapting it to CO2 valorisation.

"When we started working on photochemistry in the group we realised that commercially available setups were not practical, especially for multiple reaction sets, due to the inability to control reaction parameters such as irradiation intensity," says Sergio Tatay, a researcher in the Ramón y Cajal programme at ICMol and coordinator of the AVI-approved project.

"We were interested in designing a new photoreactor to better facilitate our exploration of photocatalysis at multiple scales and applications. Other researchers have also noted the limitations of these initial configurations with several alternative solutions reported by multiple commercial groups and suppliers in recent years", Tatay added.

AVI's programme of valorisation and transfer of research results to companies requires collaboration with another technology centre or company. In this case it is the Instituto Tecnológico Metalmecánico, Mueble, Madera, Embalaje y Afines (AIDIMME), which will be in charge, among other issues, of aligning the product with current regulations. Funimat, a multidisciplinary team, has been assembled, comprising chemists, innovation agents and a mechatronics engineer. The project will run for three years and is supported by the IDA with a grant of 221,000 euros over this period.